乙烯產量

Producing ethylene requires a constant focus on efficiency. Maximizing production while minimizing operating costs is crucial in order to stay competitive. To help you achieve your target production costs and capacity as well as secure production reliability, partner with Alfa Laval. Our proven technology helps meet the growing demand to deliver high yields – reliably and cost-effectively.

Optimizing ethylene production processes

Planning to increase your production capacity or reduce your energy bill? Alfa Laval can help. We have vast expertise as a trustworthy supplier of high performance solutions for the petrochemical industries - across the globe. Our deep application knowledge and strong local presence means that we are always ready to help you – from initial planning to commissioning and continuous service.

Experience has proven that investments in more efficient heat exchangers are very profitable. Return on investment is often realized in less than a year. Consider that heat recovery of an extra 10 MW is equivalent to:

- An annual fuel or steam consumption of 3 MEUR

- A reduction of 880 m3/h in cooling water consumption

- An annual CO2 emissions reduction of 17,500 tonnes

This is based on the assumptions that:

- Steam price (10 bar) = €20/tonne

- 8,400 operating hours/year

- Fuel (natural gas) contains 48 MJ/kg

- Cooling water ?T = 10°C

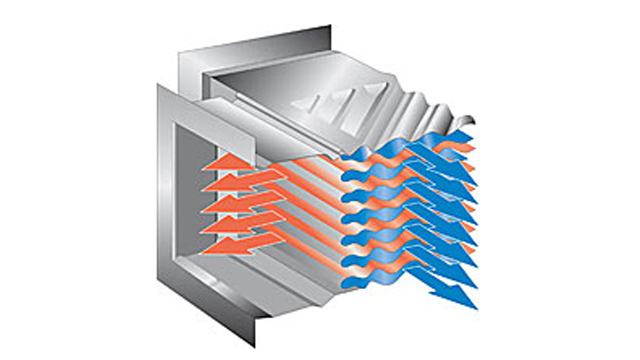

Alfa Laval’s compact heat exchangers can help you raise plant efficiency by:

Saving energy – The high thermal efficiency means that you can recover more energy with Alfa Laval’s compact heat exchangers. You can use energy sources previously deemed worthless and make your entire plant run on heat recovered from the cracker. Excess steam can then be sold to neighbouring plants.

Reducing bottlenecks – More efficient heat exchangers and more heat recovery can solve bottlenecks related to heating and cooling. One example is the first compressor stage, where capacity can be increased by improved cooling in the quench tower.

Increasing uptime – Alfa Laval heat exchangers are built to withstand the toughest conditions. Our transfer line exchangers are specially designed for maximum reliability. With our compact heat exchangers you experience minimum fouling and easy cleaning.

Reducing environmental impact – Better heat recovery can lead to lower CO2 emissions and/or reduced consumption of cooling water. If your production is hampered by restrictions on cooling water flow rates or return temperatures, improving heat recovery may be an easy solution to the problem.