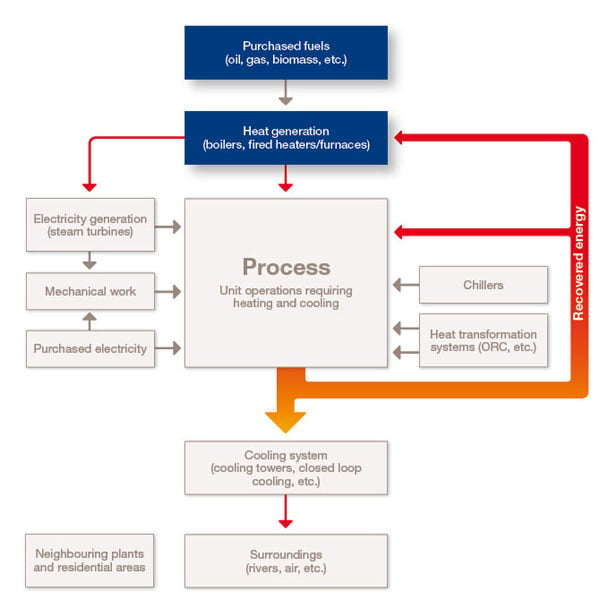

Process heat is usually generated in steam boilers and/or in fired heaters/furnaces. In both cases, waste heat recovery can lead to substantial fuel savings.

Recovering waste heat often reduces the need for steam in a plant. Consequently the boiler’s fuel consumption is reduced, as are greenhouse gas emissions and the load on the cooling system.

Recovered heat can also be used for preheating the boiler feed, lowering fuel consumption.

The fuel consumption of a fired heater/furnace can be reduced by using waste heat from the plant for preheating the heater feed. Again, this reduces fuel bills, cooling system load, and greenhouse gas emissions.

Heat can be reused in the heat generation system to preheat the feed or the combustion air. It can also be used directly in the process. In both cases the load on the heat generation system is lowered, and in turn fuel consumption.